Mold Fill Analysis

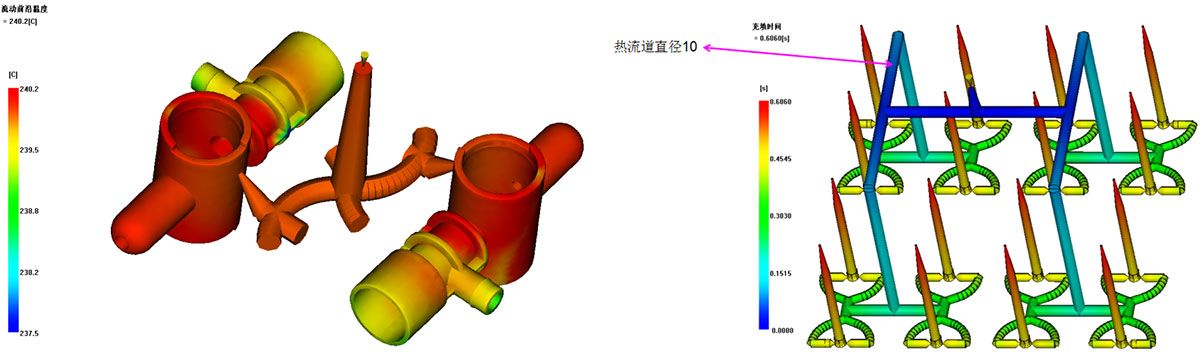

To ensure optimal results, we utilize AUTODESK mold-fill simulation software; a computer aided 3D simulation of how the mold fills, packs and cools during the injection molding process is generated. This allow a proactive approach to processing problems or potential concerns that can be solved before manufacturing begins and provide insights into potential manufacturability and quality issues.

By completing a comprehensive DFM analysis, we are able to determine the optimal; gate location, wall thickness, rib locations and cross sections, cooling line locations, and much more.